UX // Branding

Takeoff Technologies

Lead UX Designer

Figma

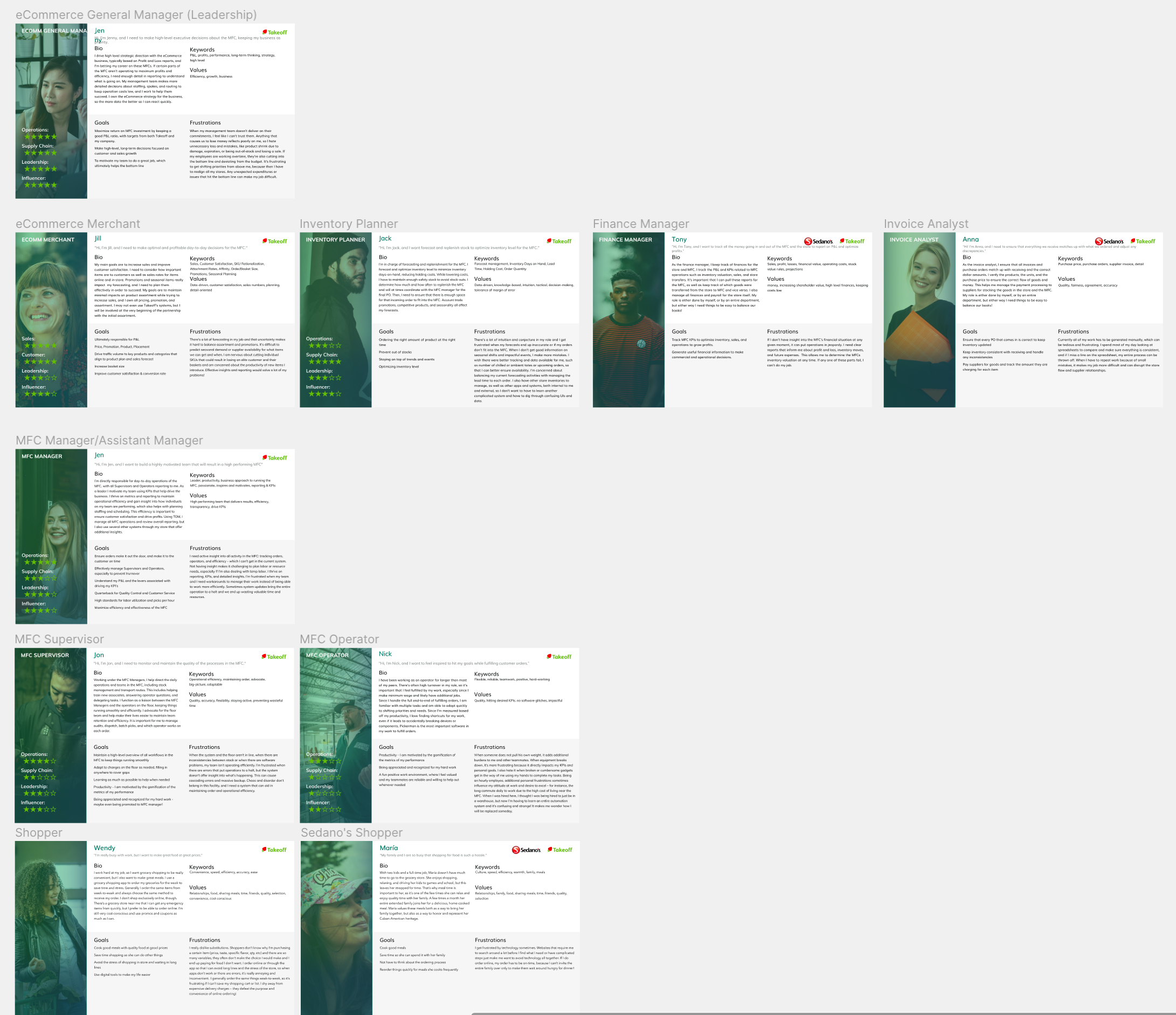

Takeoff provides eGrocery solutions to grocery partners via the use of micro fulfillment centers (MFCs), which can be thought of as similar to industrial sized vending machines. After product is placed inside the machine, the product can be fetched far more quickly than cumbersome in-store methods. This allows fast eGrocery pickup and delivery, clean and uncluttered grocery floors, and separate operations to keep eGrocery running smoothly.

However, despite the efficiency of the large machine (called an OSR), certain items must be picked for a customer order outside the machine. Examples of these items include cut flowers, newspapers, cases of soft drinks or other items too large to fit inside, or soft, delicate items like peaches. For some of these items, it makes sense to stock them close to the machine, in a designated picking area. For other items, it makes sense to keep them in the grocery store itself. Our system had to be able to track the locations of items for all these areas. In order to manage these items, the grocery store employees will either use a special wrist-attached horizontal Android device, or view the high level overview of the system on a PC.

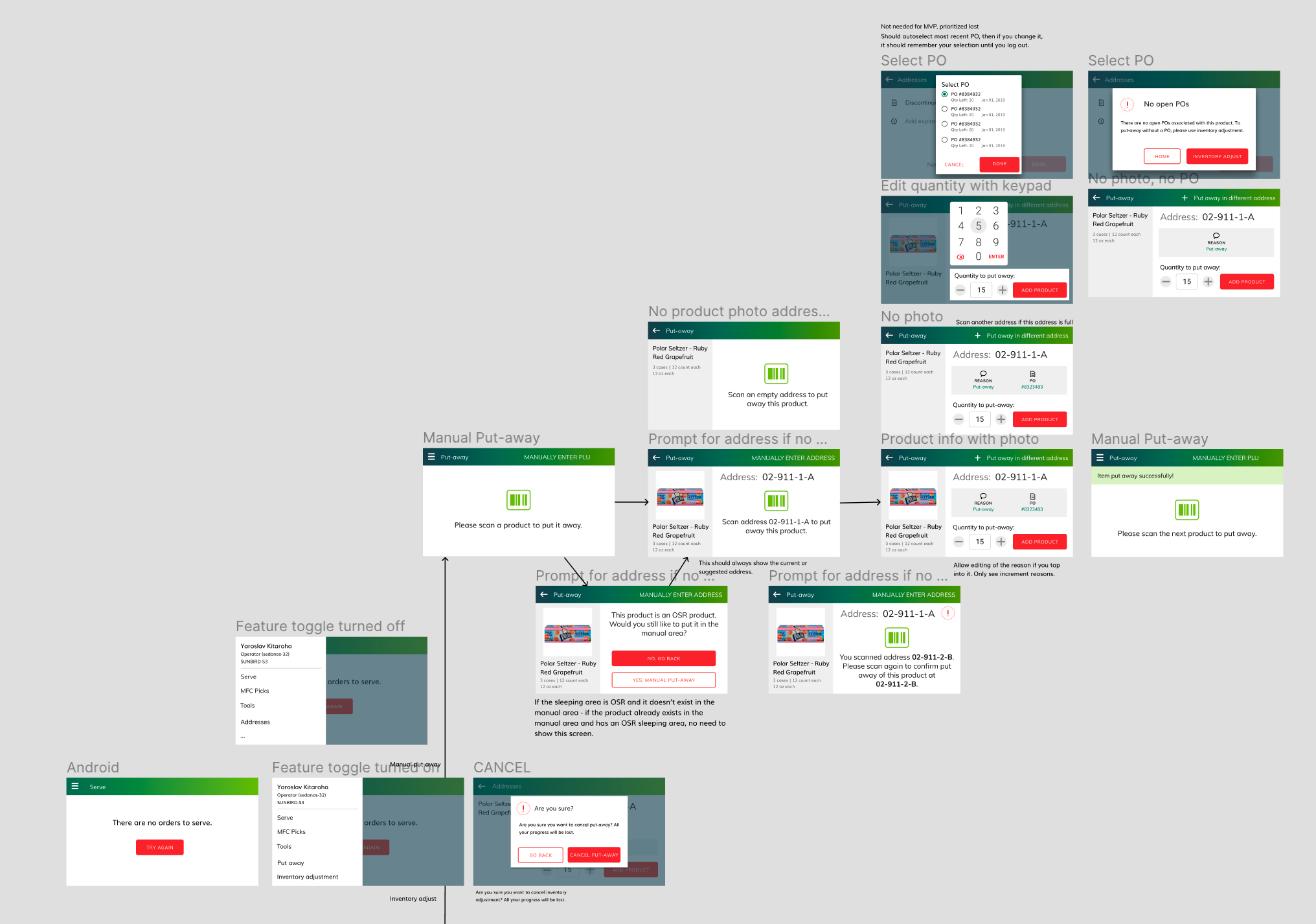

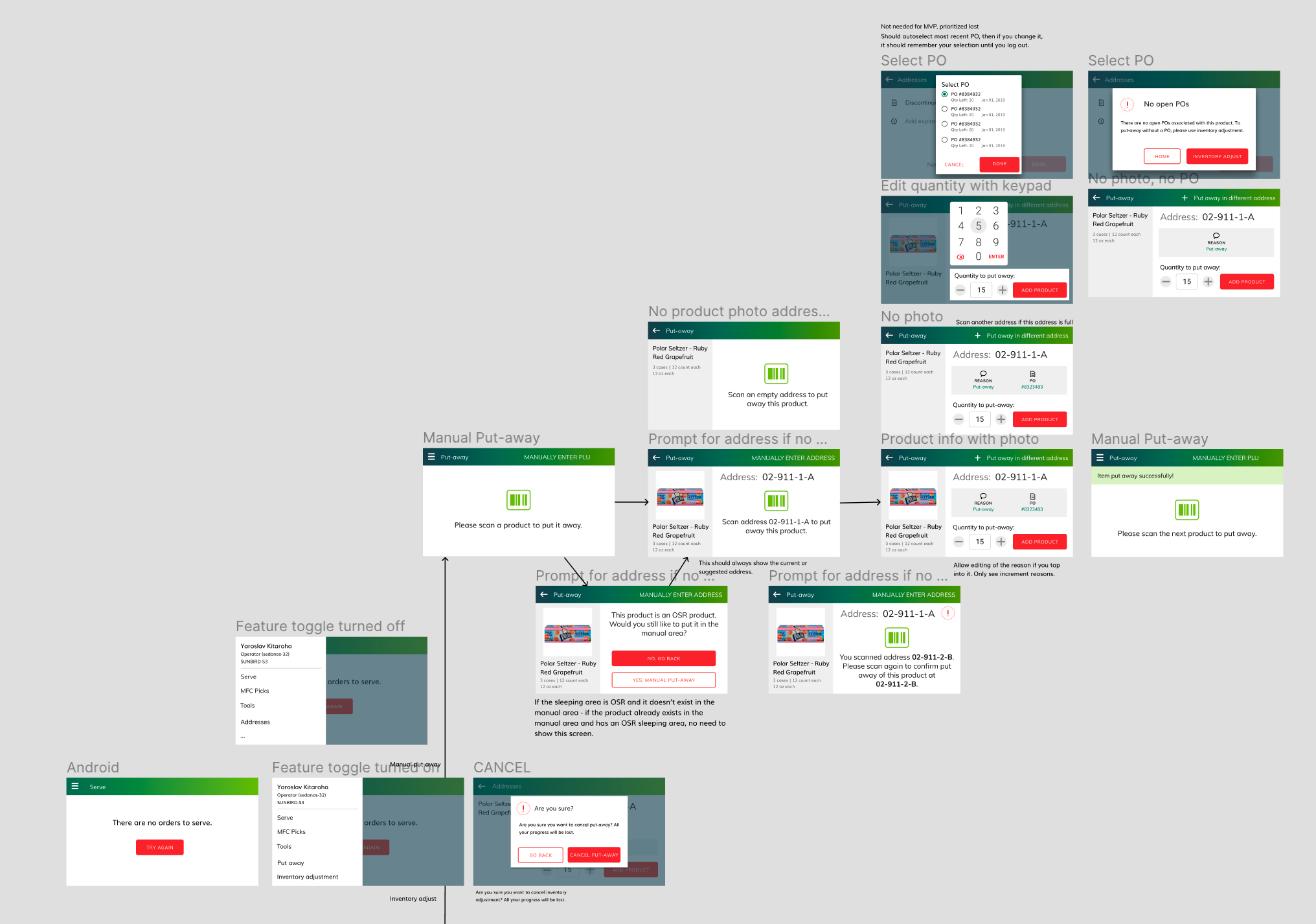

Above are mockups for the manual put-away flow. This will allow workers at the grocery store to receive an order of groceries off a shipping truck and place it in the correct area. The system will flag a product if it is supposed to go into the OSR machine or into a separate designated area (called the sleeping area). It will also flag other edge cases, like if there is no existing designated sleeping area.

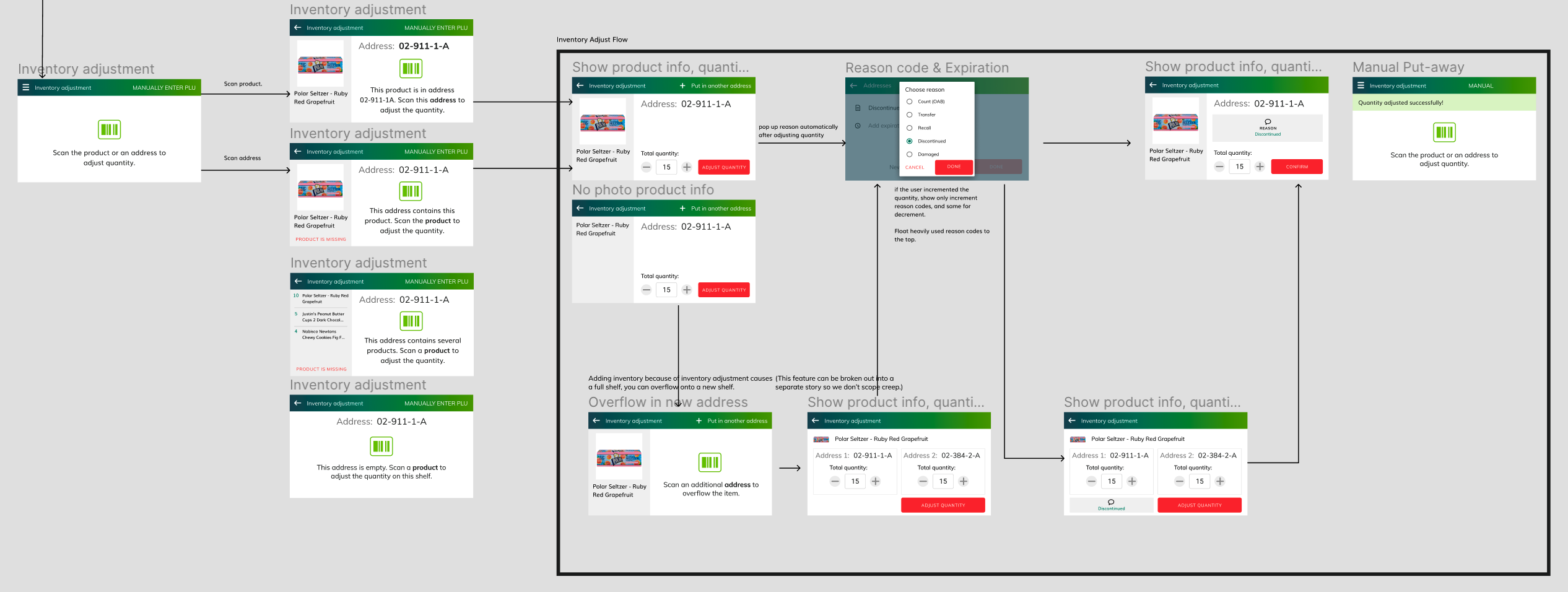

A similar flow is inventory adjustment. This is a feature for quality-assurance checking in each area and necessary in case someone grabs an item from the store to stock the MFC sleeping area. Edge cases here include if a sleeping area contains multiple types of products (like two different types of soft drink) and if adding more inventory overflows it into the adjacent designated area.

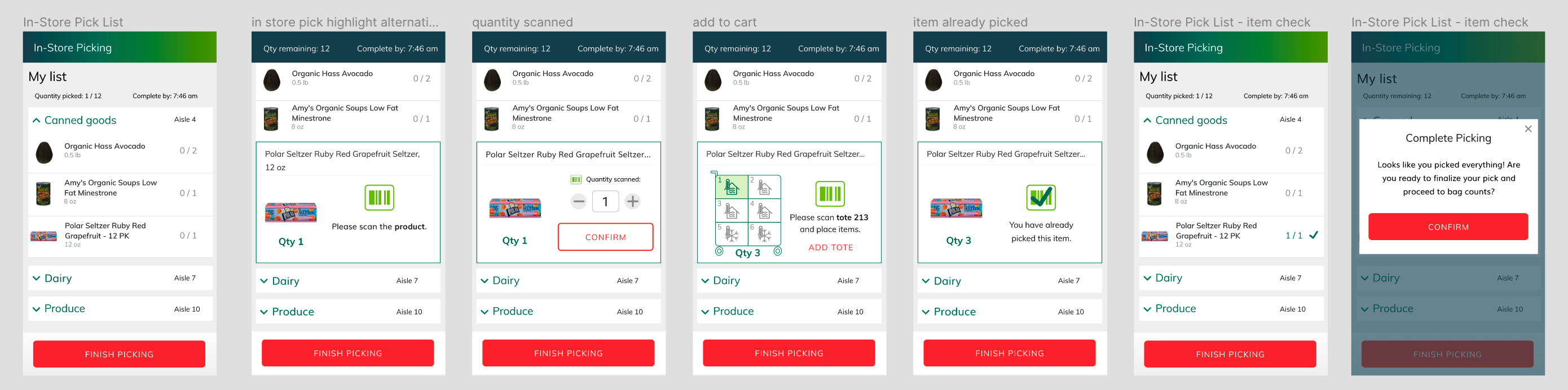

Finally, employees must be able to pick the items if they're located in the grocery store itself. These items are sorted by aisle, NOT by order, to allow for the most efficient packing. Employees push a cart with totes on it, and the totes are visually represented in the mockups along with their label, so employees can put the right item in the right tote as quickly as possible.

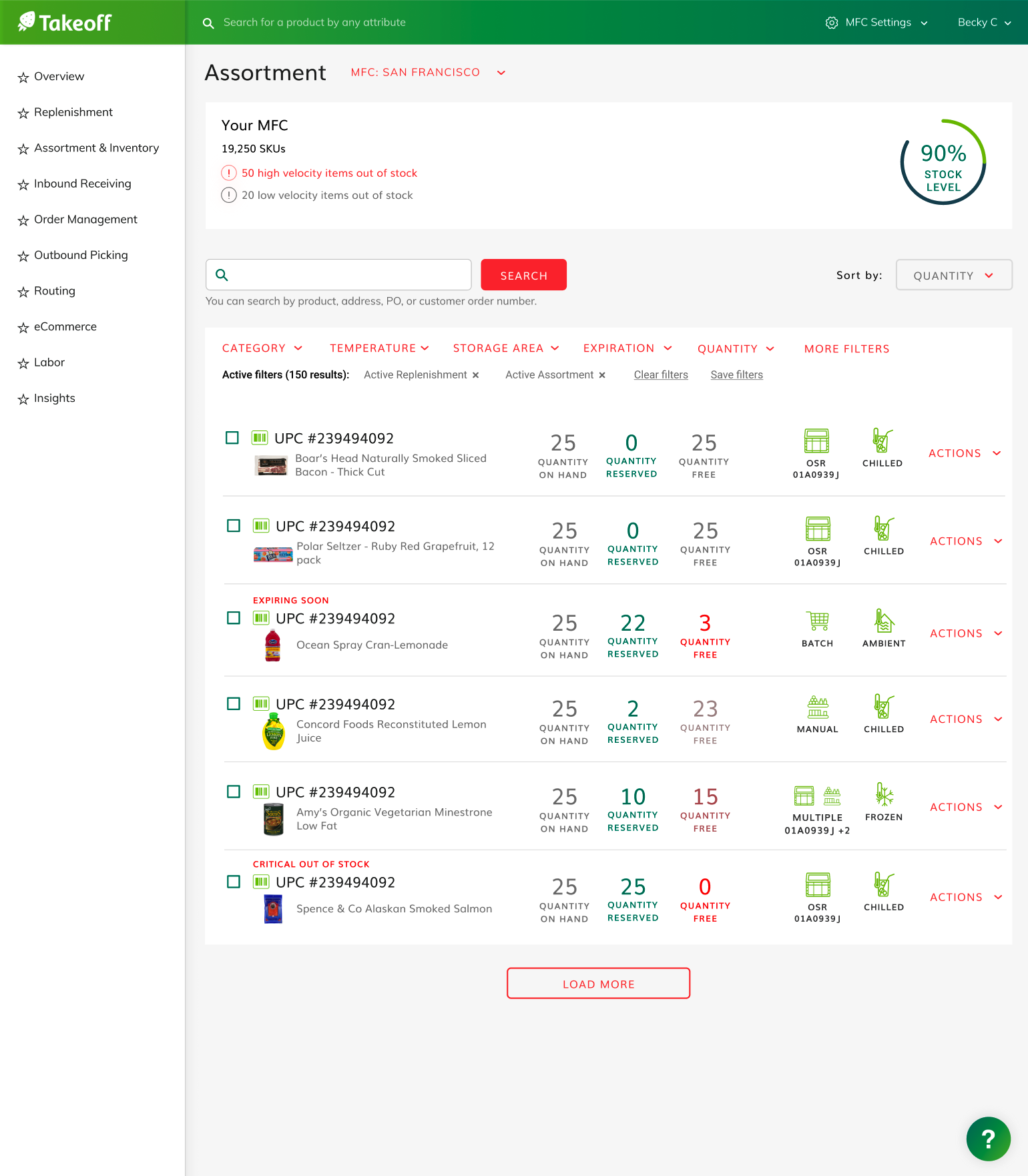

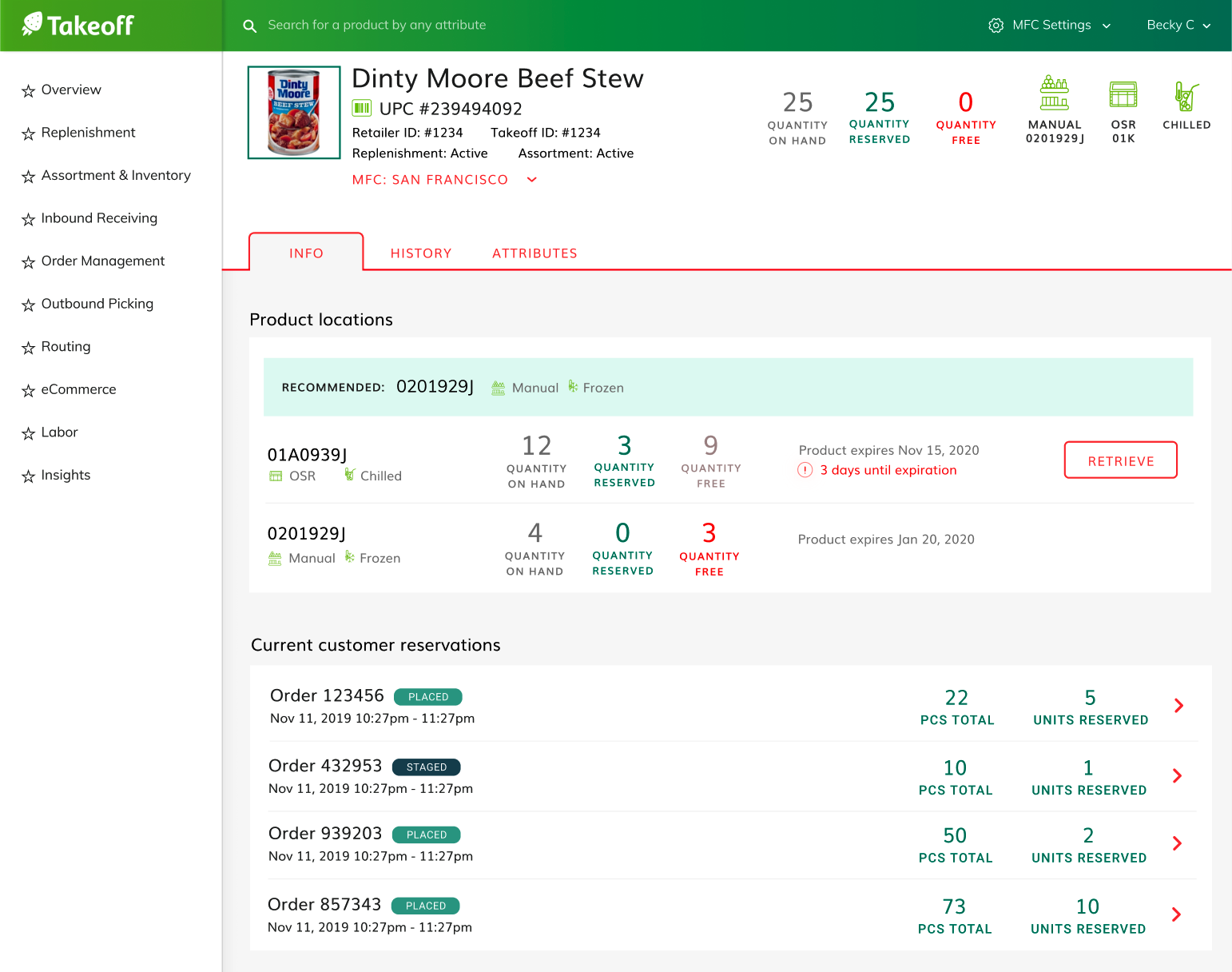

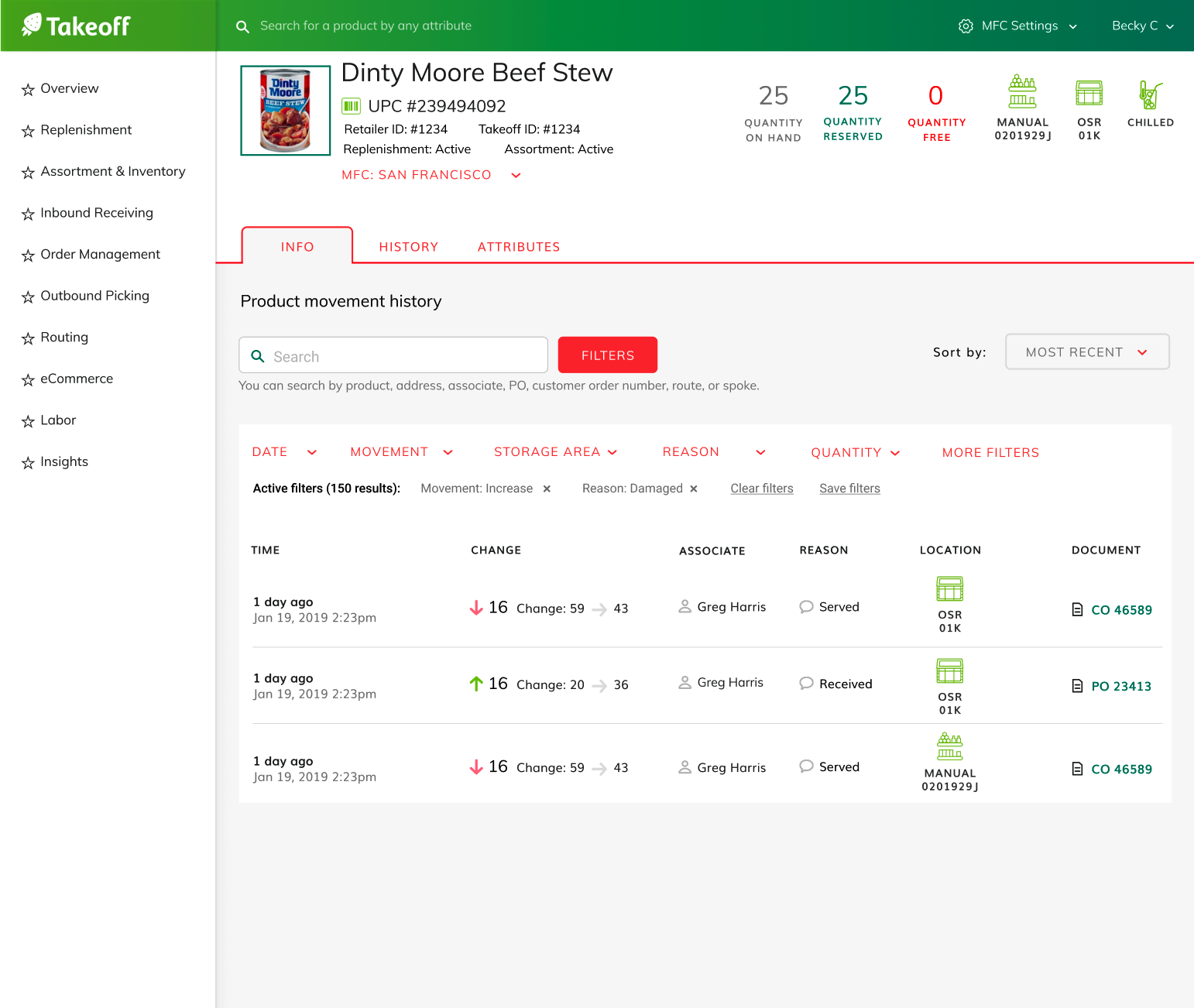

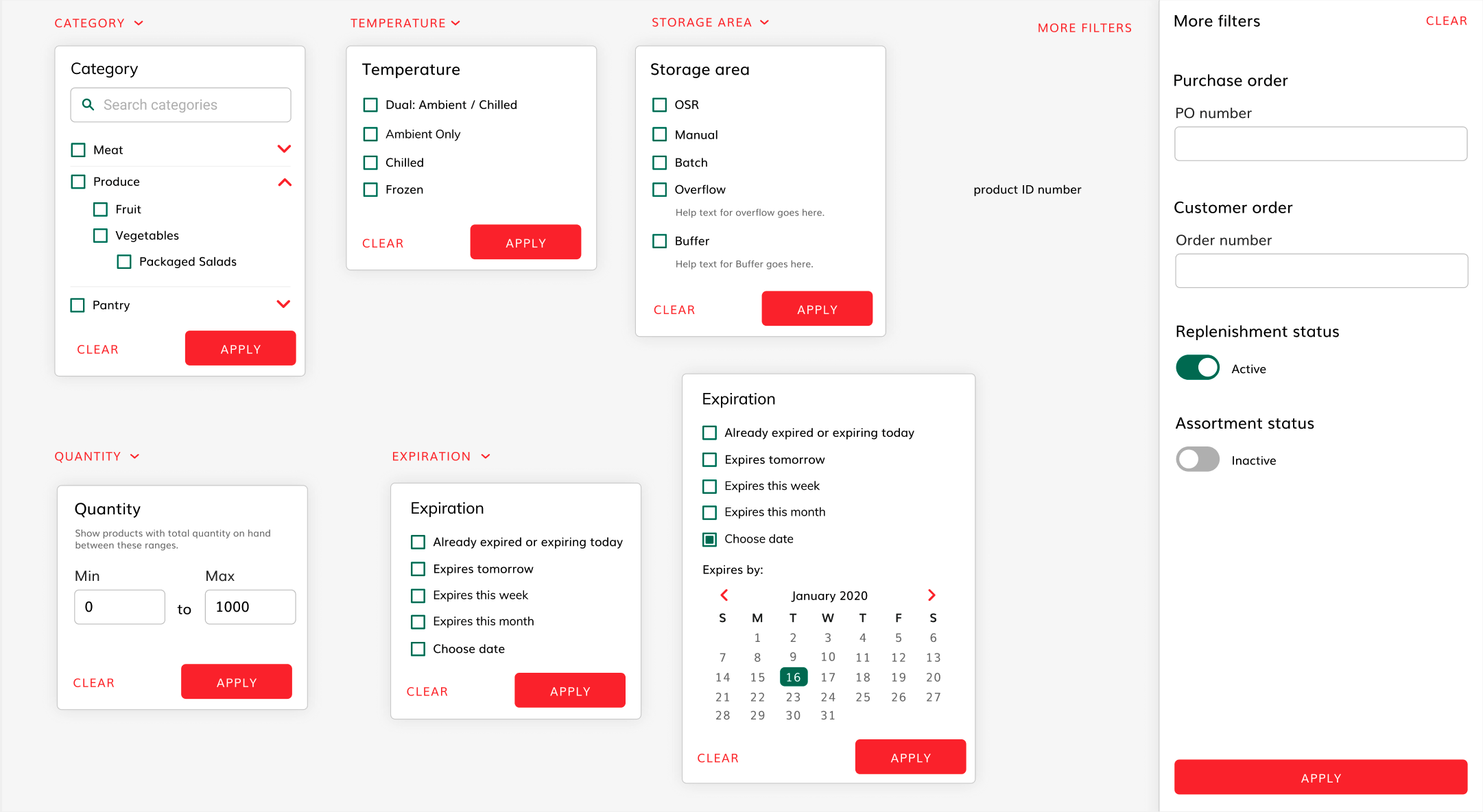

These are wireframes (not completed) for the backend management system of the entire MFC. Unfortunately, the product was not completed before I left the company. The goal with this project was to allow the MFC supervisor to see where any product is at a glance, as well as manage the state of the entire MFC, including the OSR machine, the manual sleeping area, and even in-store management. They would need to be able to make adjustments, account for new inventory and stock, and check if there are any expired products or out-of-stocks. In addition, they would need to be able to track the history of every item, as well as which employee touched which item at any given time.

Eventually, this system would be used to also manage incoming stock, delivery routing, and labor.